Advanced HVAC Diagnostics

Xencom Elemco has installed controls on over 5,000 Rooftop Units (RTU). Over the past 30 years control strategies have evolved from simple on/off HVAC control to sophisticated strategies that include; Direct Temperature Control, Demand Controlled Ventilation, Real Time Demand/Load Management, Efficiency Monitoring and comprehensive Advanced Diagnostics.

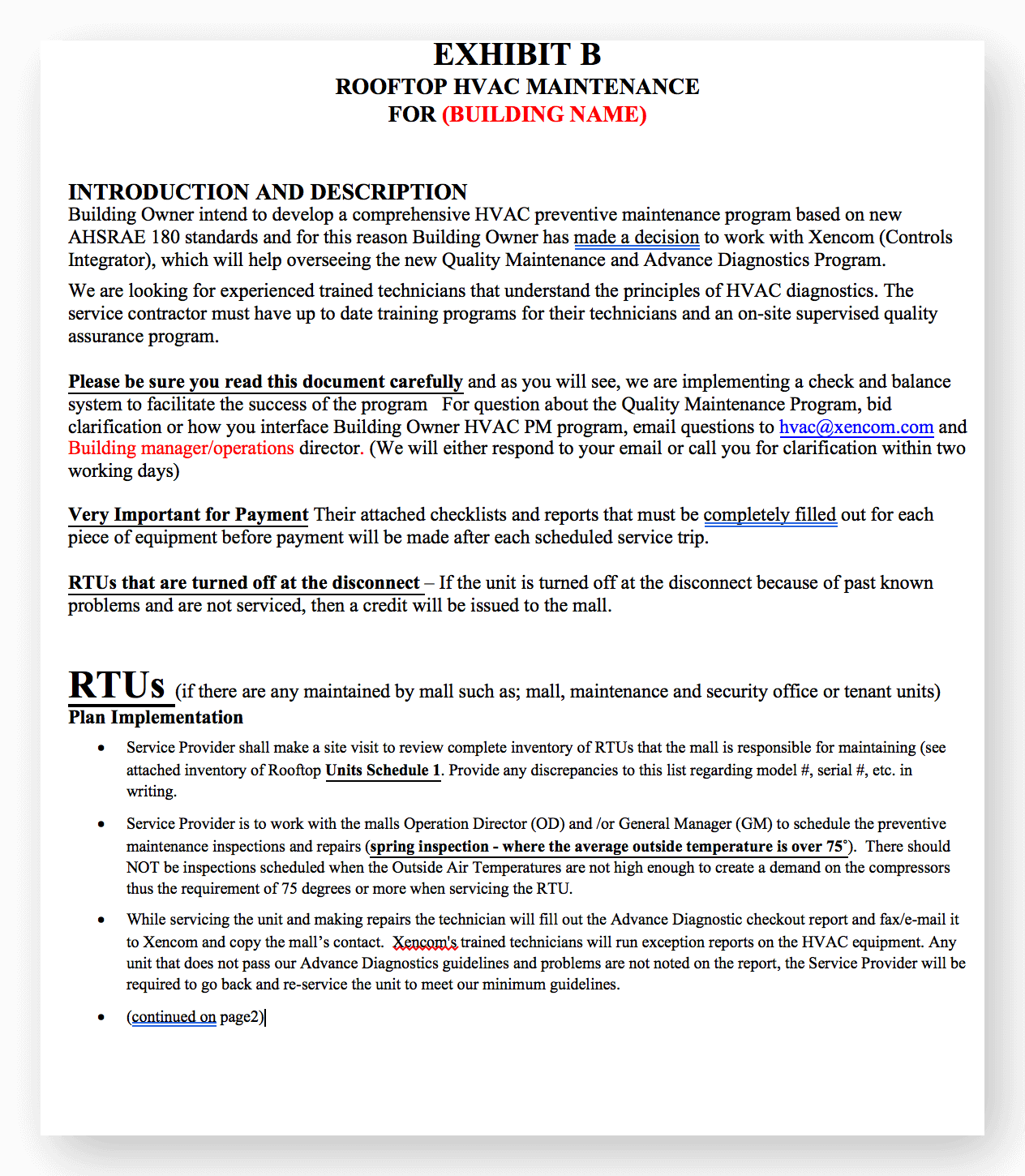

One of the major problems we have experienced in this effort is that no matter how well you control and monitor the RTUs, if the mechanical equipment is not properly maintained, the sophisticated HVAC controls cannot be optimally effective. To mitigate this issue we added Advanced Diagnostics to the RTUs and, using this data, continually help building owners/managers setup, monitor and maintain Preventive Maintenance programs. The following is an outline of our Control & PM program.

Xencom’s Advantage

Control & Monitoring– Xencom Elemco has developed Advanced Diagnostics Dashboards along with Key Performance Indicators (KPIs) to analyze the operations and performance of the HVAC Equipment. Although this segment focuses on Rooftops, we implement the same program for Central Plants (Chillers, Boilers, Air Handlers and VAV Boxes).

HVAC Control & Monitoring Strategies

Rooftop Control & Monitoring

Direct Temperature Control

Advanced Diagnostics

Analytics & Analysis

Exception Reports & Alarms

Feedback for Preventive Maintenance Reporting

Monitored Manual Overrides

Advanced HVAC Diagnostics

Xencom Elemco’s Plan: Our strategy is to use our standard energy management system inputs and information to analyze the overall performance of an RTU. We do comparisons of similar RTUs and set baseline indices from which exception reports can bring attention to RTUs that are not operating to optimum levels.

Preventive Maintenance: Using our exception reporting on alarms and performance, along with equipment runtimes, reports can be generated that can assist an HVAC technician perform both emergency and scheduled maintenance trips.

On-Site HVAC Technician Service & Diagnostics: When trained technicians service an RTU, they measure and analyze pressures, temperatures and amps. It is not our intent at this time to replicate that type of complete system checkout through the BMS with all the required installed sensor inputs. Rather, Xencom Elemco works with the mechanical contractors on this task.

Benefits and Return on Investment

- It is well documented in studies done by the Department of Energy (DOE) and the Association of Energy Engineers, that a properly maintained and controlled rooftop unit can reduce energy use by15% to 35%.

- On most of our projects we have seen a 15% to 25% reduction in energy use with paybacks typically less than 3 years

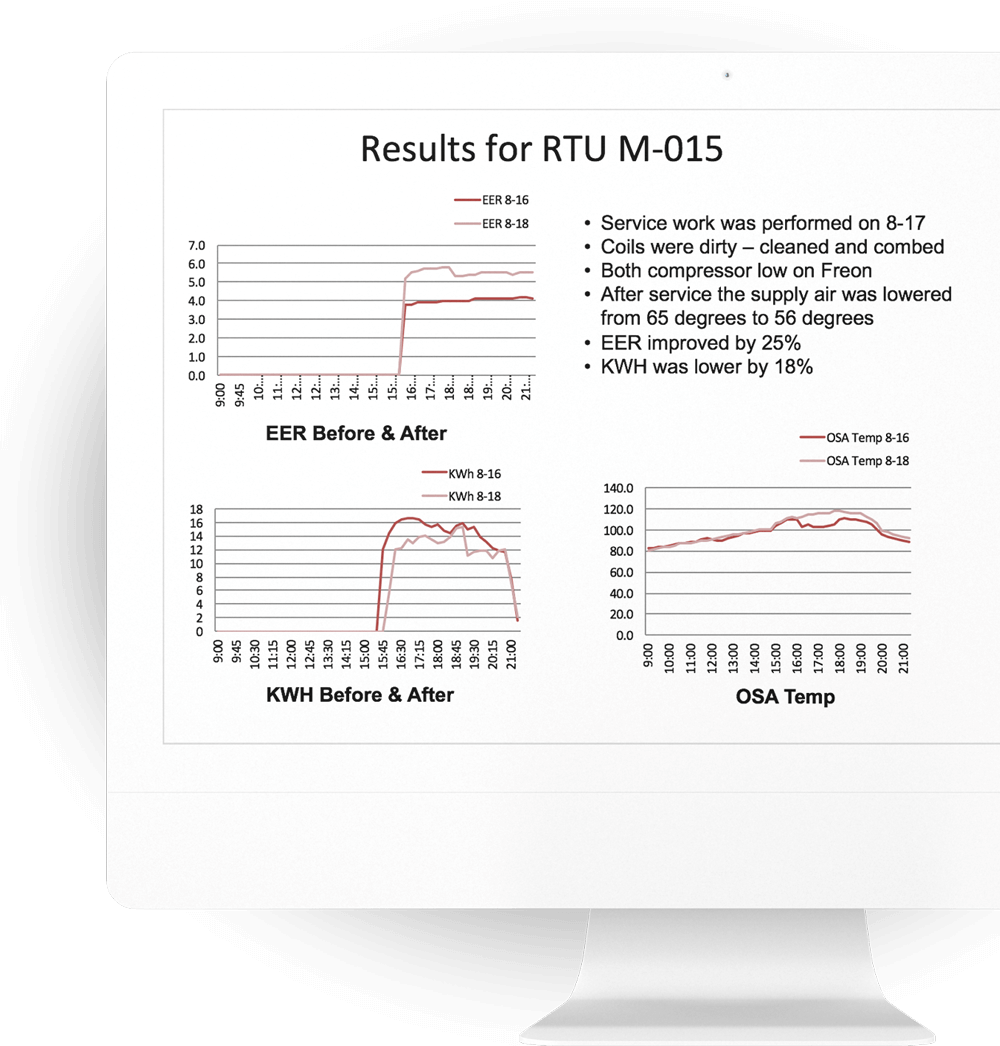

- This chart is an example of reduced costs due to implementation of Quality PM along with BMS Advanced Diagnostics. As you can see, we increased the efficiency of the unit by 25% and reduced energy usage proportionally.

Maintenance Approaches (US DOE)

Excess costs over projected normal life cycle cost;

- Reactive – $18/hp/year more than projected

- Preventative – $13/hp/year more than projected most o

- Predictive – $9/hp/year more than projected

- Xencom’s Approach (Predictive-Preventative) – $6/hp/year more than projected

Projected savings/cost avoidance’s on a 10 ton RTU over the life of the unit could exceed $3,600.

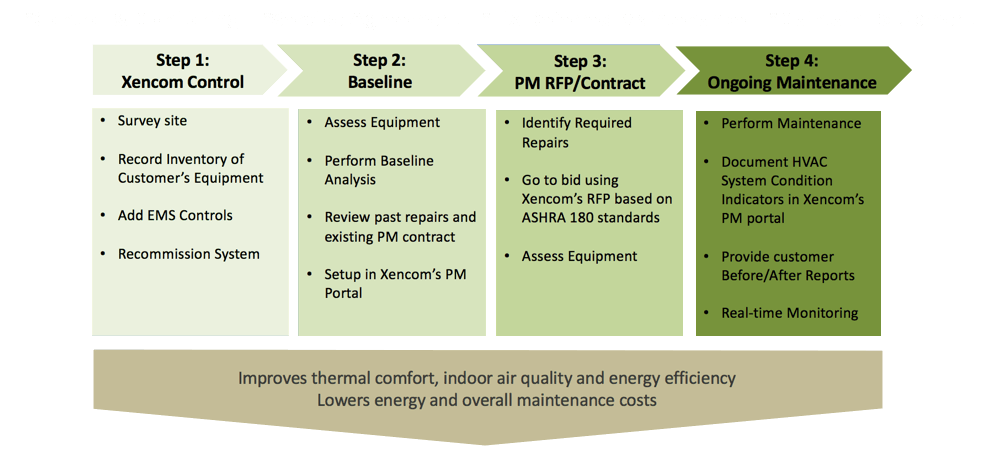

Program Overview: HVAC Control & Diagnostics

Step by Step Process

Xencom Elemco has developed a step by step approach to intelligent maintenance practices through our custom Advanced Diagnostics and Analytics. We have included Predictive Maintenance based on interval-data analysis of system efficiency variances. Using Real Time monitoring of Key Performance Indicators, we notify our customers and/or their Mechanical contractors of current or imminent equipment issues via email or text.

Implement a Preventative Maintenance Program

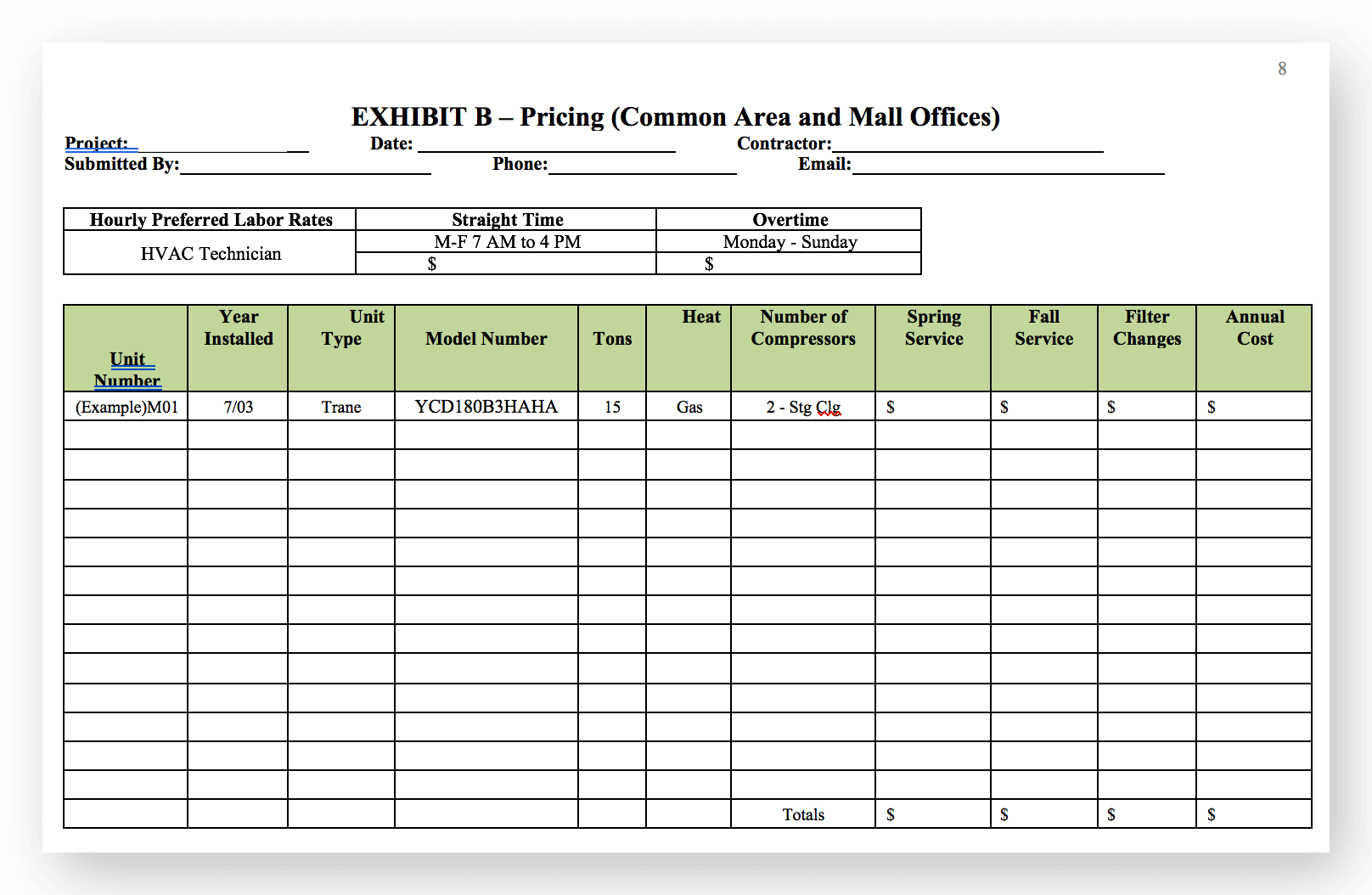

Request for Proposal (RFP)

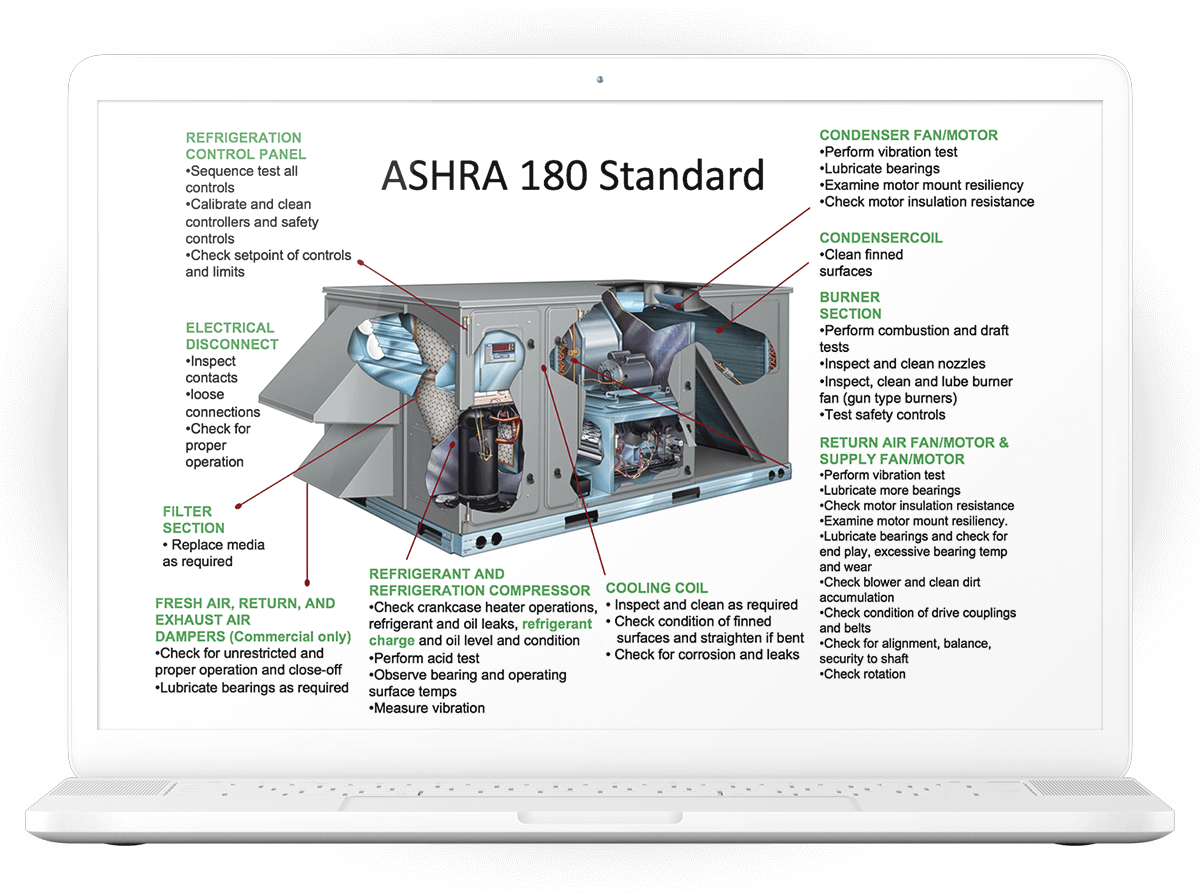

- Based on ASHRA 180 Standards

- Detail Scope of Work

- Penalties if the Work is not Completed

- Detailed Terms & Conditions

Detailed Equipment List

- Manufacturer

- Model & Serial Number

- Cost per Serviceable RTU – (Only unit that are operational)

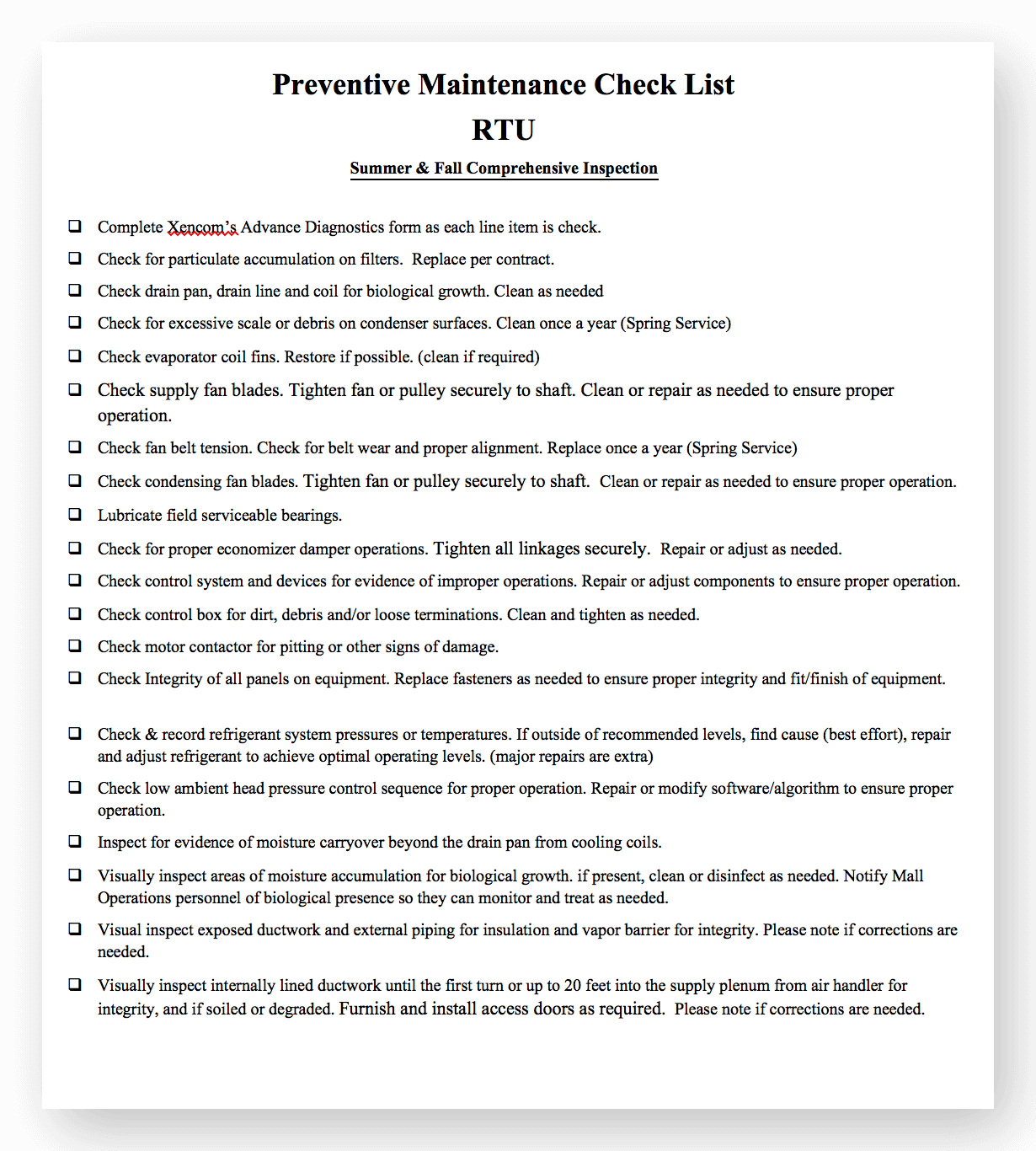

Detailed Checklist

- Line by Line Checklist

HVAC Diagnostics

Preventive Maintenance Portal

Preventive Maintenance Portal

FEATURES AND BENEFITS

Xencom Preventive Maintenance (PM) Portal

- Contract Management

- Equipment Tracking

- Repairs and Invoices

- Warranty Info

- Longevity Reporting (Time to Replace the RTU)

Input Screens for PM Inspections

- Line by Line Checklist

- List of Repairs

- Tracking of Essential Indicators

- Temperatures

- Pressures

- Amps

- Must Pass Minimums Requirements

- Subcooling

- Superheat